Built to Exceed

Sauer Mechanical is at the Forefront of High-End Mechanical Projects.

WHO WE ARE

Since 1876, providing professional construction services which exceed our customers’ expectations.

About Sauer Mechanical

Our project experience includes new installations, renovations, prefabrications, design builds and the installation of heavy mechanical services including process piping, cryogenic piping, central energy plants, deluge systems, and traditional mechanical systems.

After opening an office in North Florida in 1970 to pursue industrial mechanical work, Sauer evolved into an industry-leading general and mechanical contractor. Today, Sauer Mechanical is a subsidiary of Sauer Southeast, based in Jacksonville under which there are three additional subsidiary companies, providing clients access to a full range of mechanical, construction, and structural services.

Sauer Mechanical has offices in: Jacksonville and Cape Canaveral.

Jacksonville & Orlando:

Specializing in multiple commercial markets for plumbing and mechanical work.

Cape Canaveral:

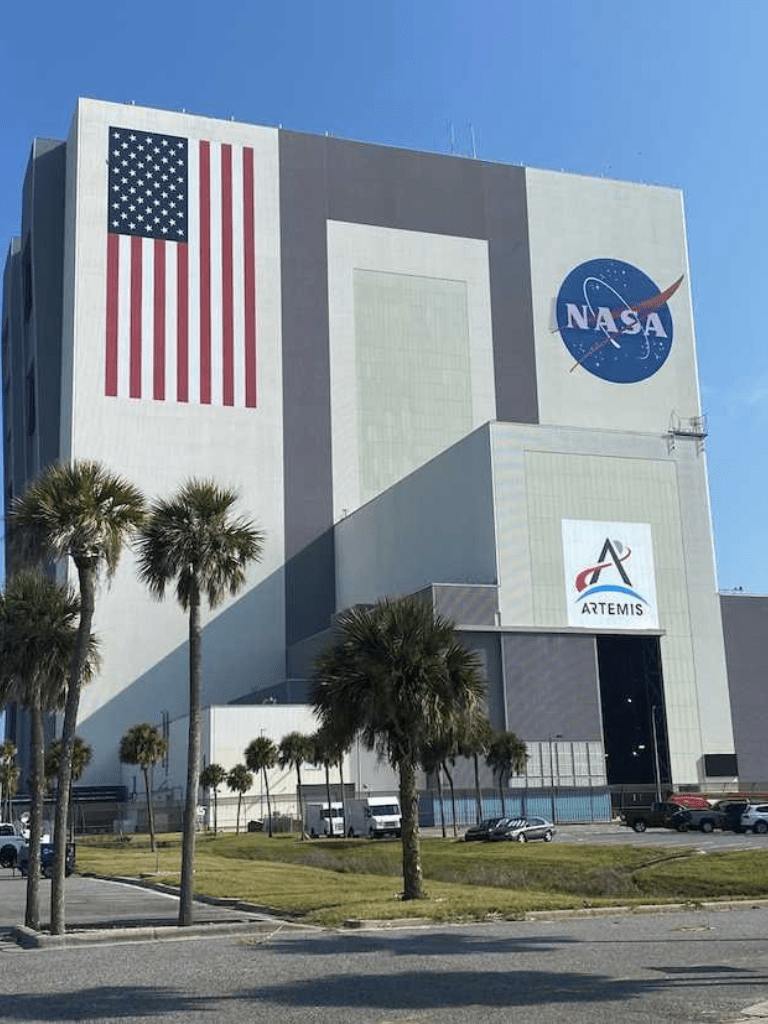

Specializing in the Defense and Space industries with ongoing work at the Kennedy Space Center in Cape Canaveral.

Federal:

Specializing in mechanical and plumbing work on Federal sites throughout the Southeast

OUR PROJECTS

Project Showcase

Utility Annex Repairs at Launch Complex 39, VAB

Johnson & Johnson

Vulcan Launch Infrastructure

OUR PROJECTS

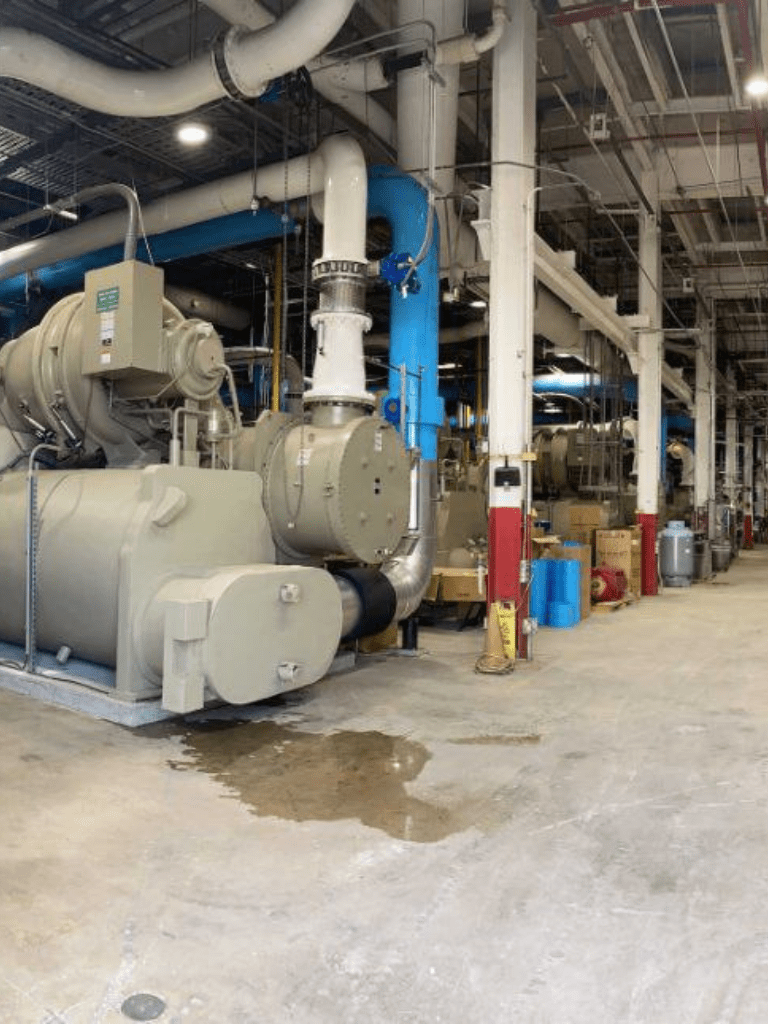

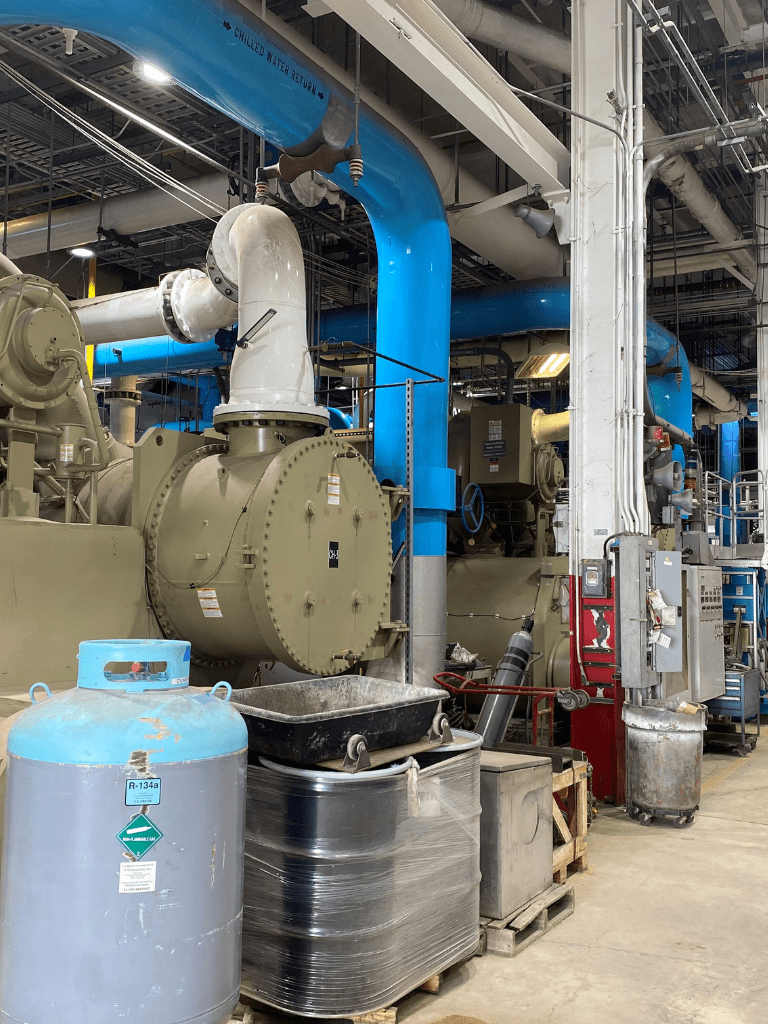

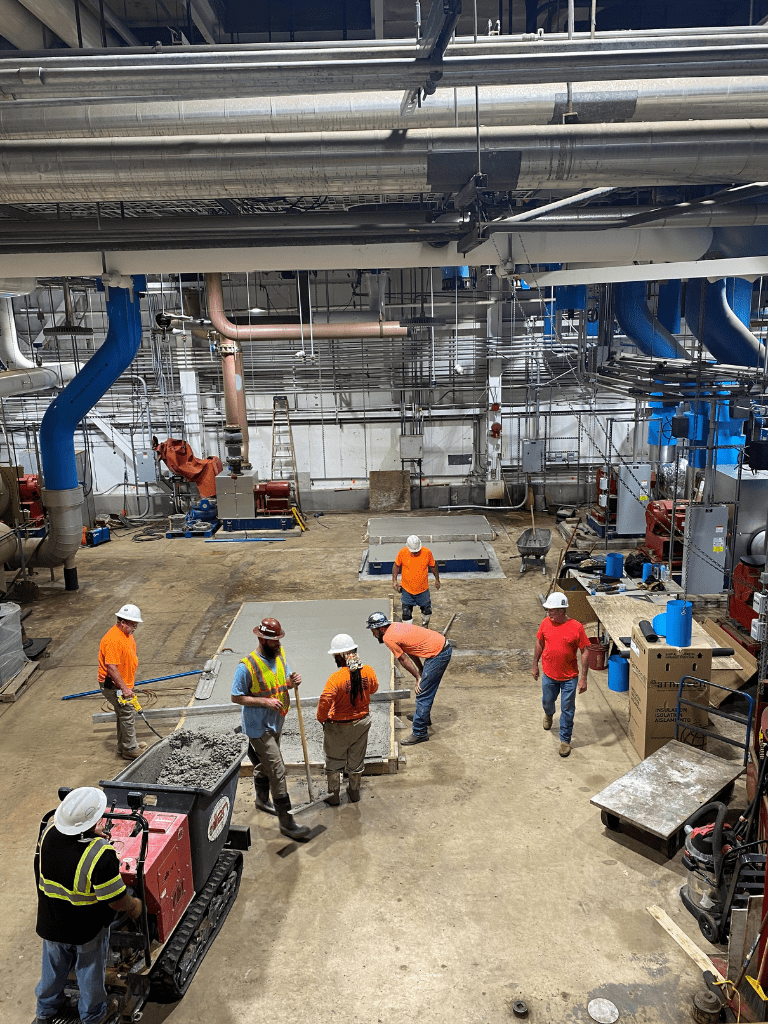

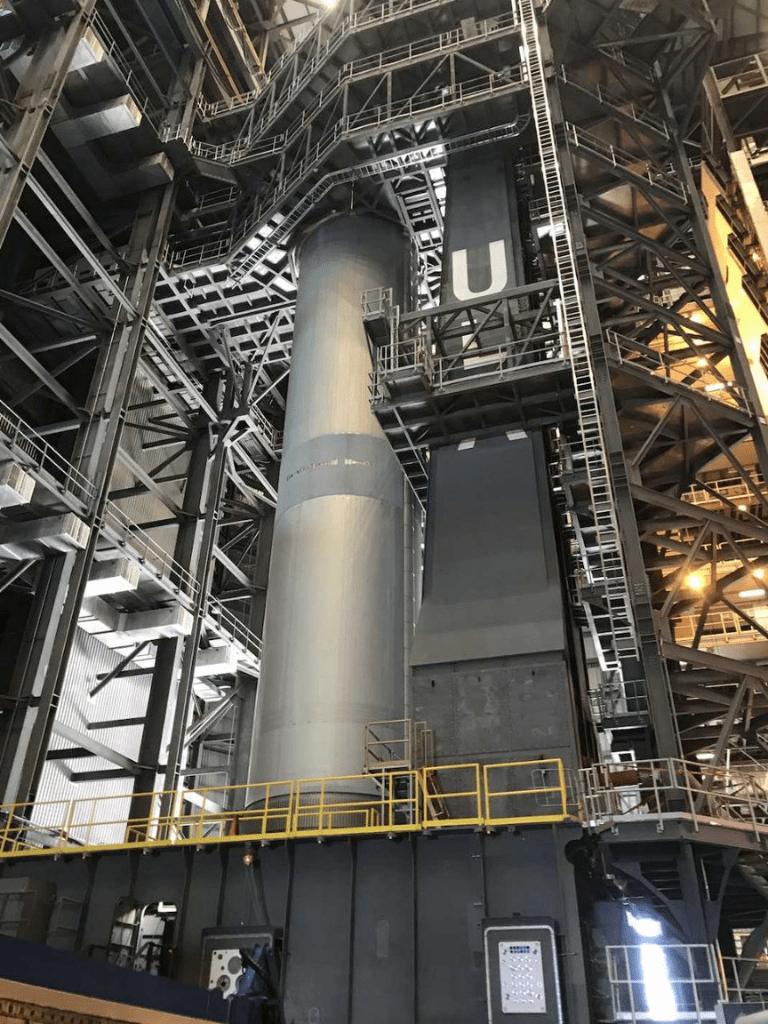

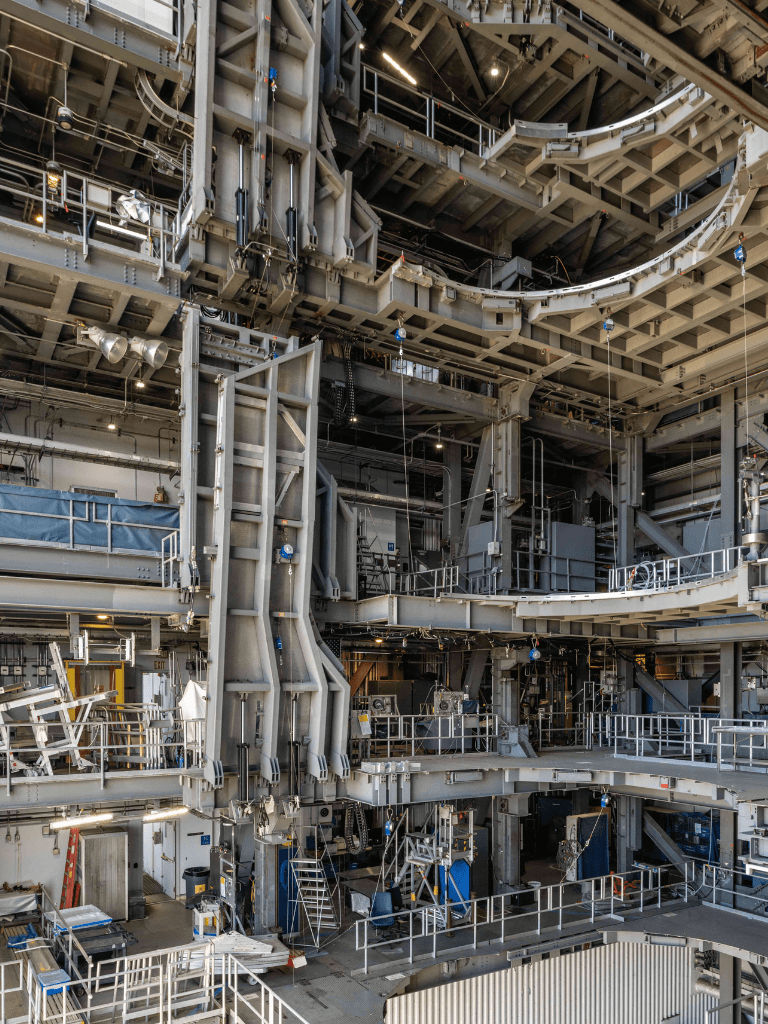

Utility Annex Repairs at Launch Complex 39, VAB

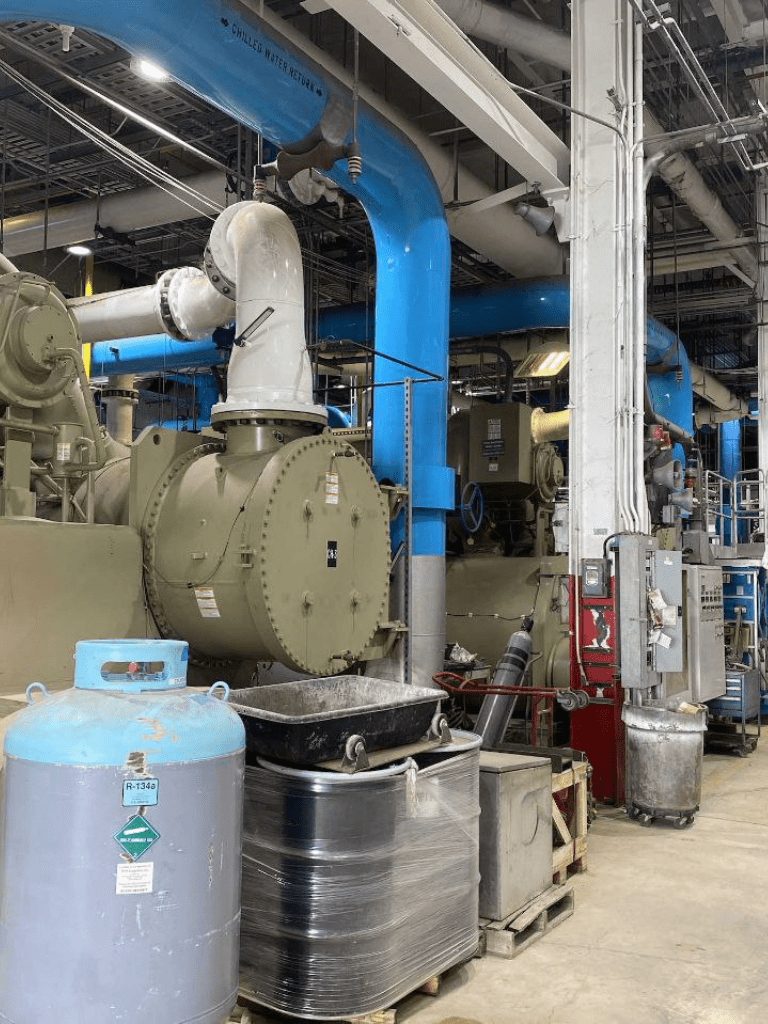

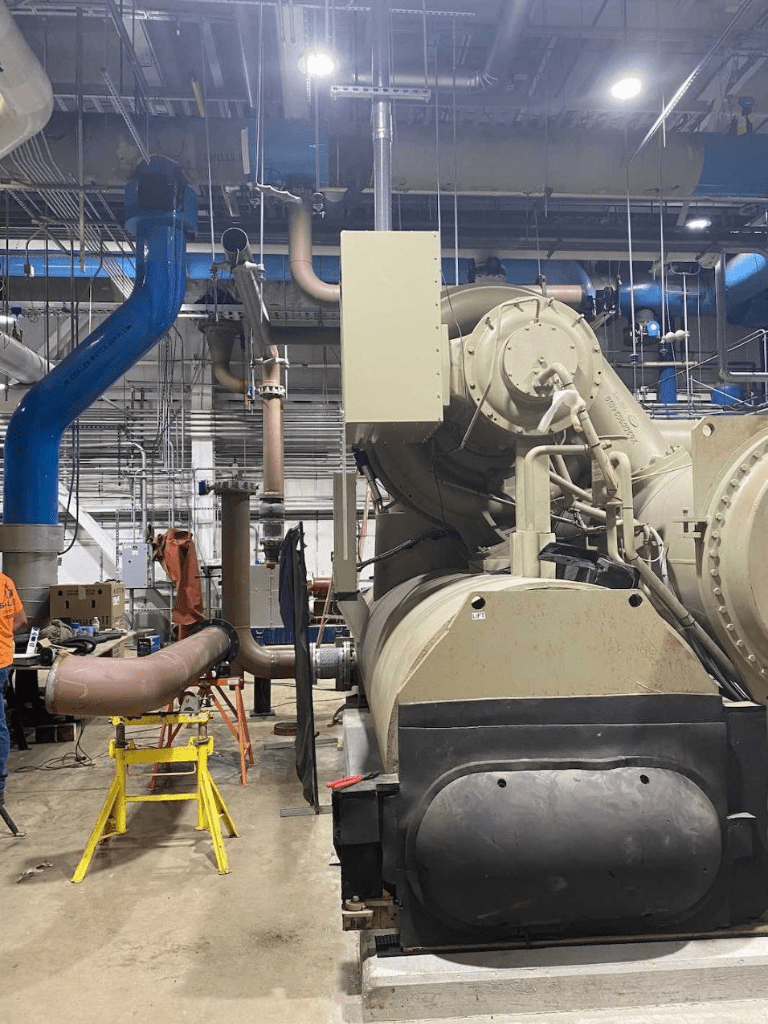

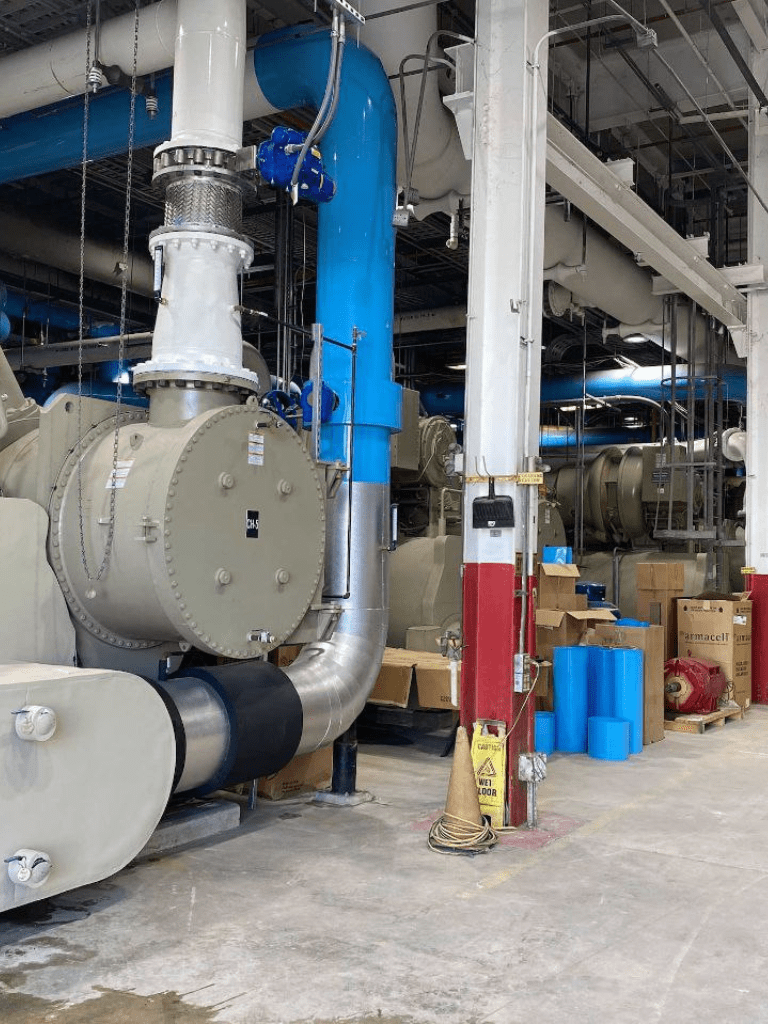

Project Name: Utility Annex Repairs at Launch Complex 39, VAB

Cost: $37,725,130

Project Description: This project encompasses a series of upgrades and removals at the NASA Kennedy Space Center’s Utility Annex, an integral facility supporting both the Vehicle Assembly Building (VAB) and Launch Complex 39 (LC-39). Specifically:

- Removal of five chillers with a combined capacity of 10,000 tons.

- The integration of selected chilled condenser water piping.

- The inclusion of primary and secondary pumps.

- The installation of associated accessories and support structures.

- The update of controls relevant to the chilled and condenser water systems.

OUR PROJECTS

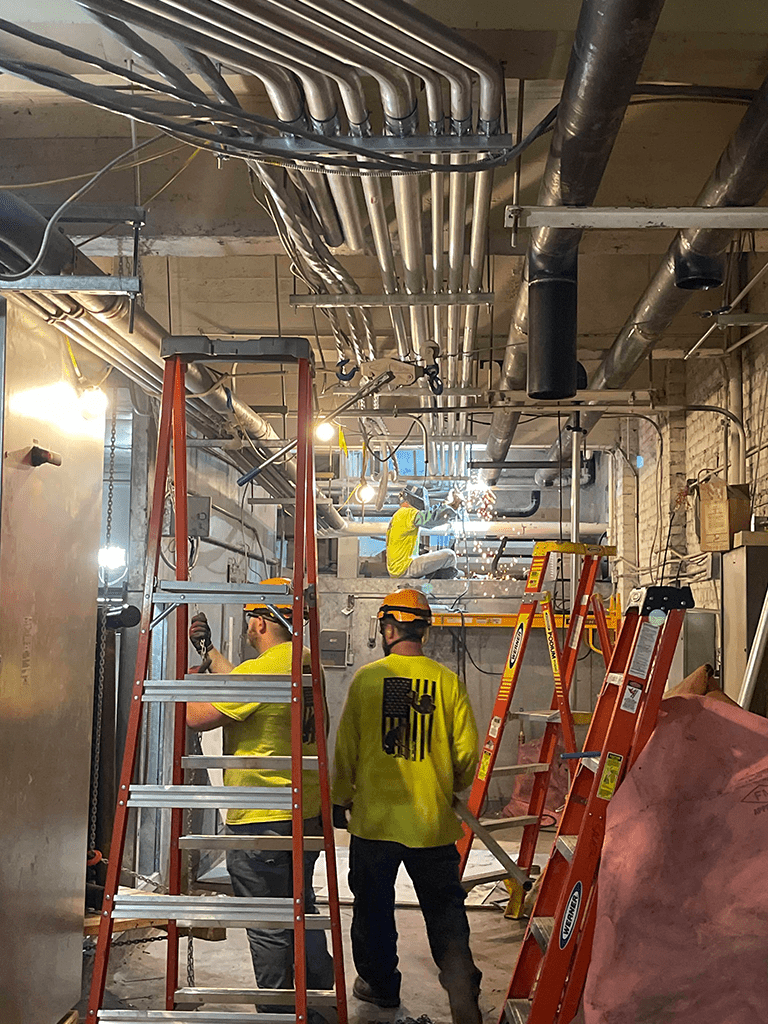

Johnson & Johnson

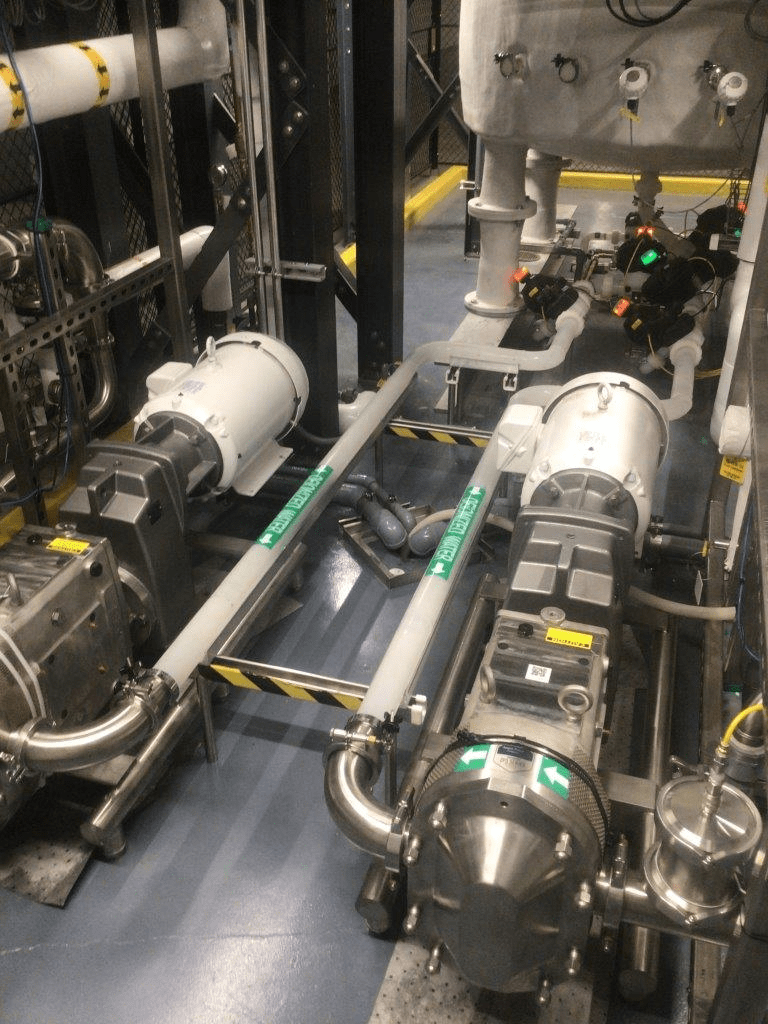

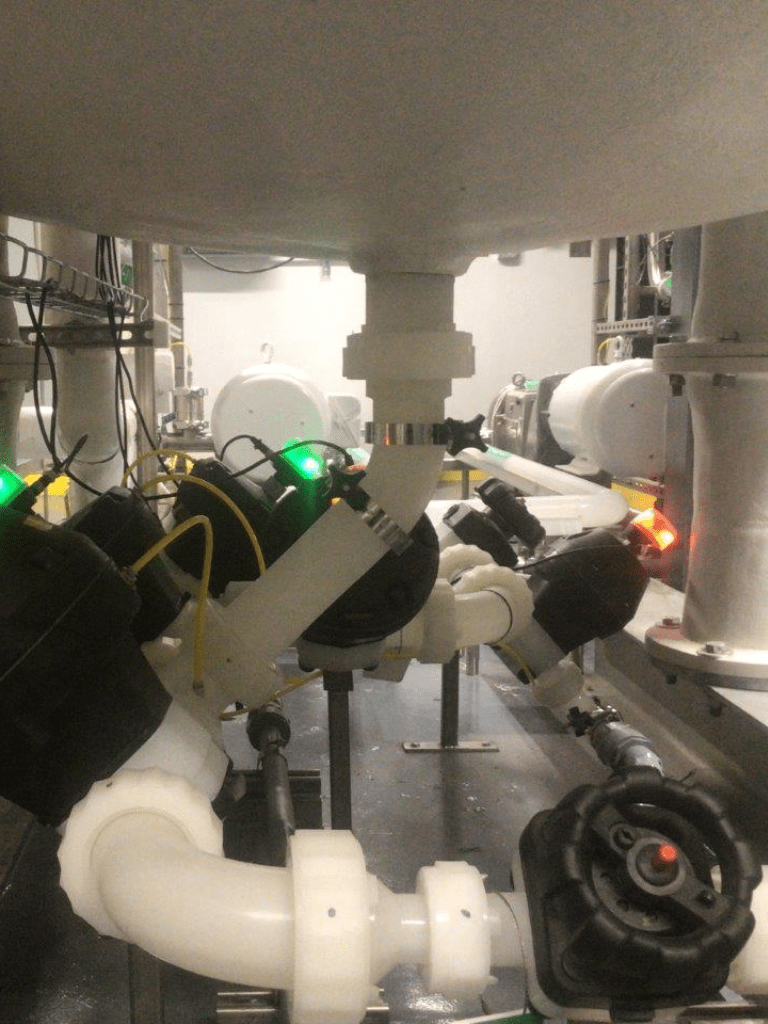

Project Name: Installation of DI System, Tank, and DIK Pumps for Johnson & Johnson Vision, Jacksonville, FL

Project Description: Sauer Mechanical collaborated with Johnson & Johnson Vision in Jacksonville, FL, to upgrade their water purity and circulation systems, essential for their vision product manufacturing.

Key Deliverables:

DI System: A state-of-the-art Deionization (DI) System was integrated to remove total dissolved solids from water, meeting the high-quality standards of Johnson & Johnson Vision’s manufacturing processes.

DI Tank: A high-capacity tank was installed, ensuring a consistent supply of deionized water for facility operations.

DIK Pumps: Specialized pumps were introduced to ensure the optimal flow and distribution of deionized water throughout the plant.

OUR PROJECTS

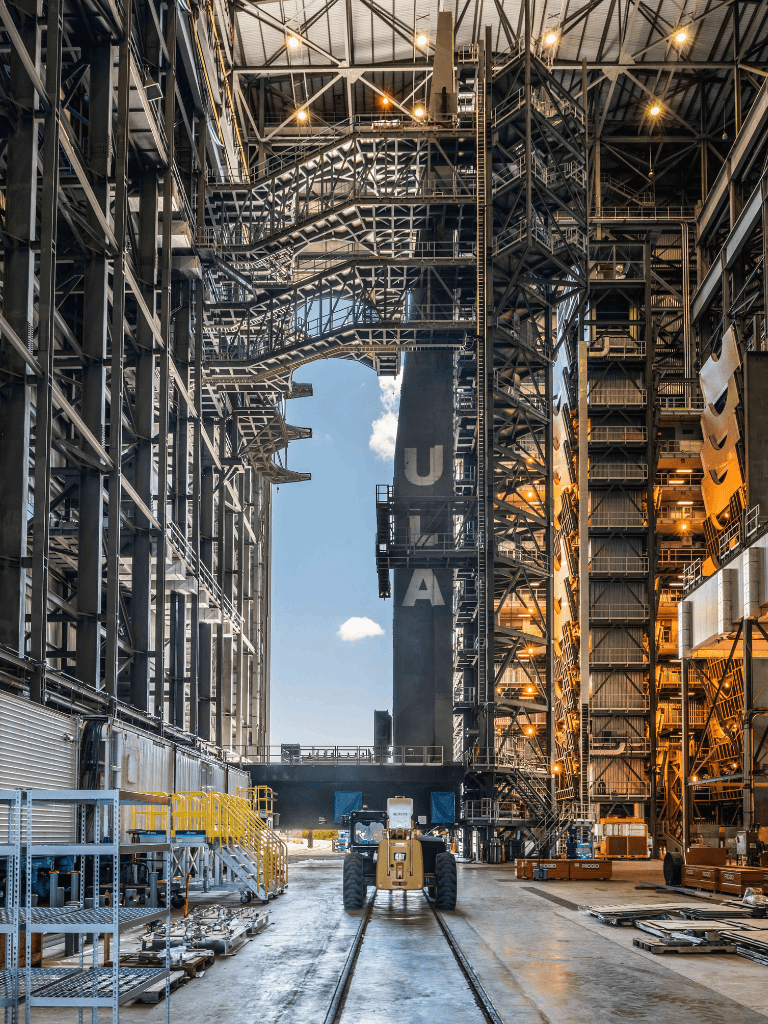

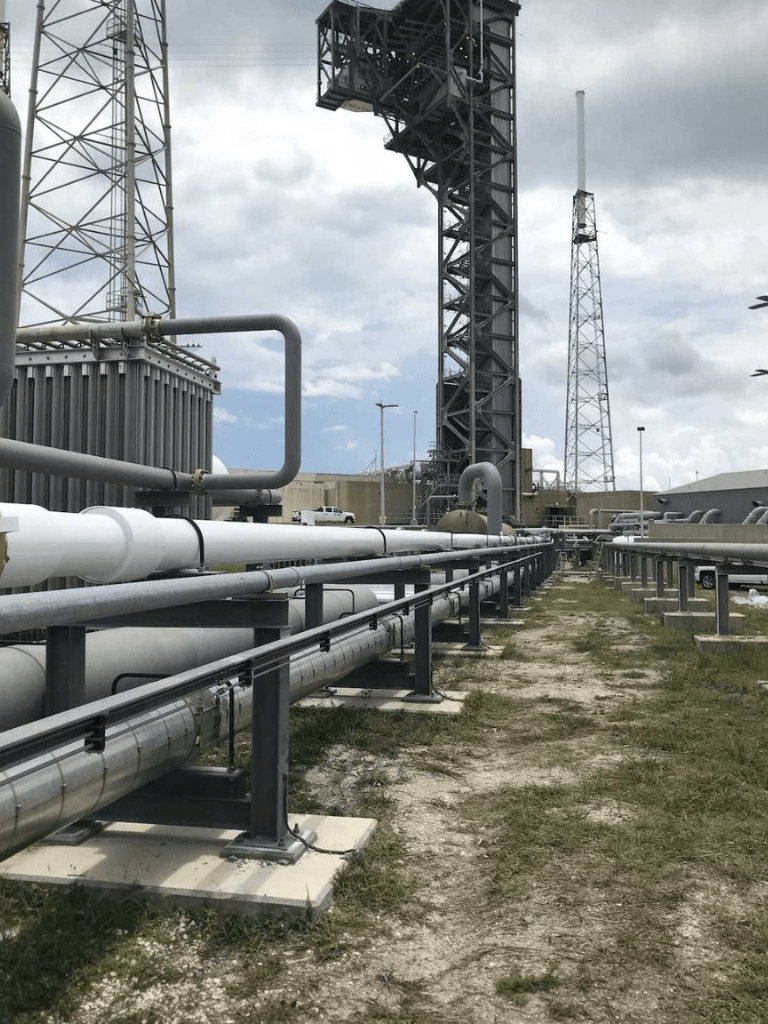

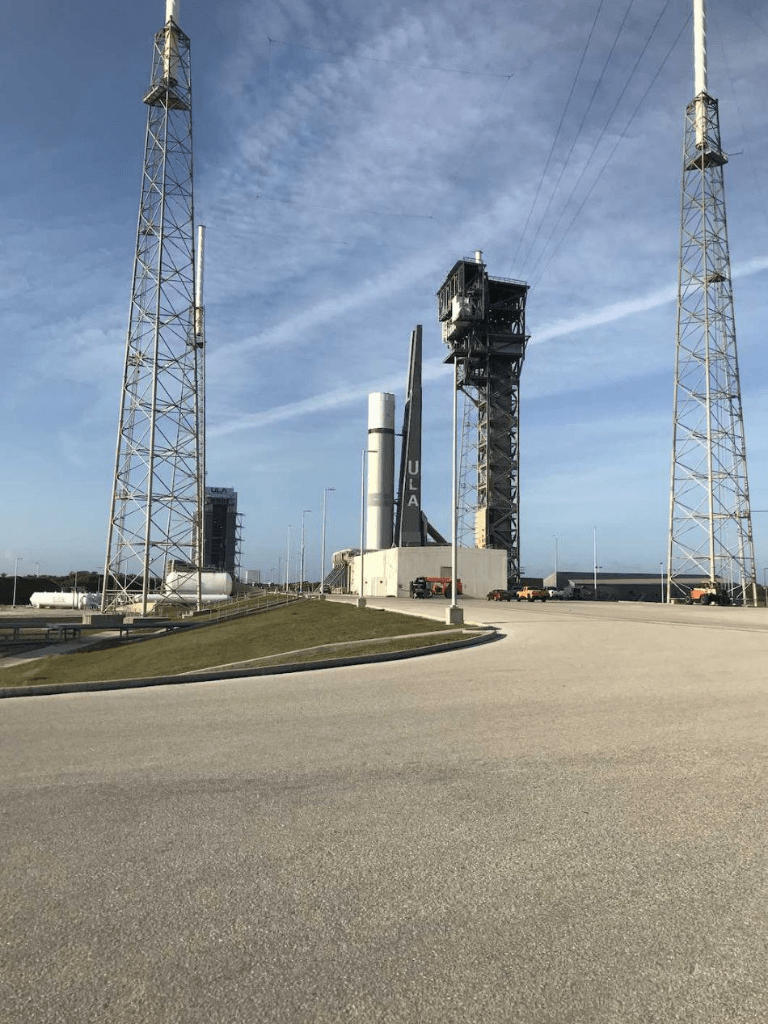

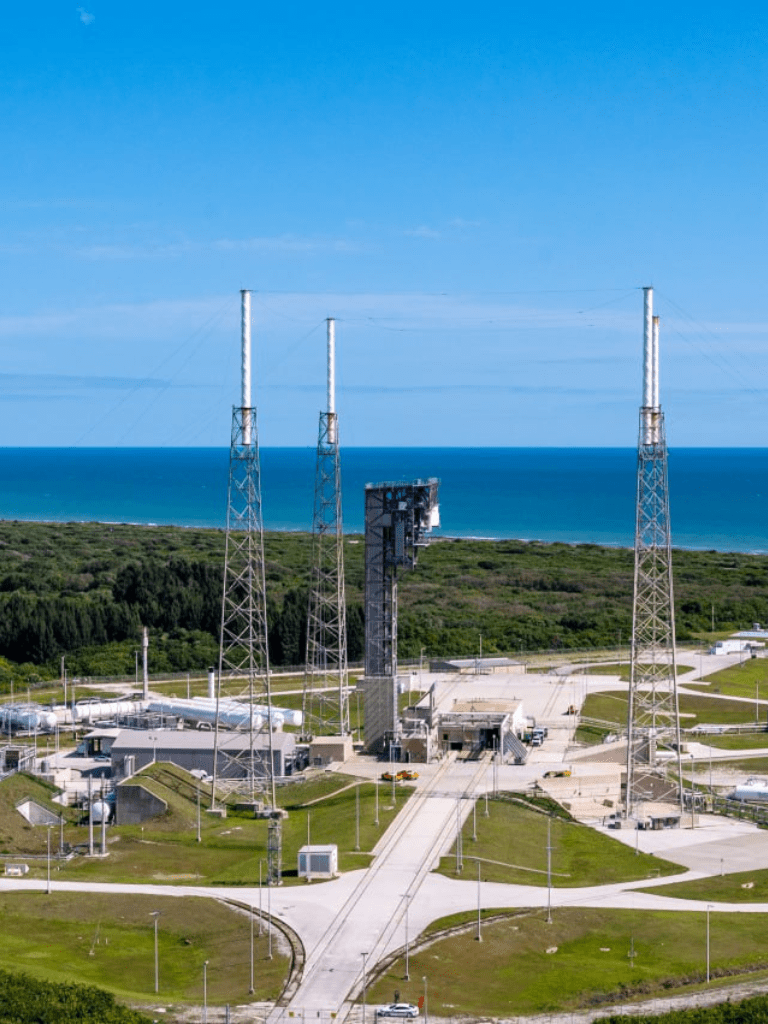

Vulcan Launch Infrastructure

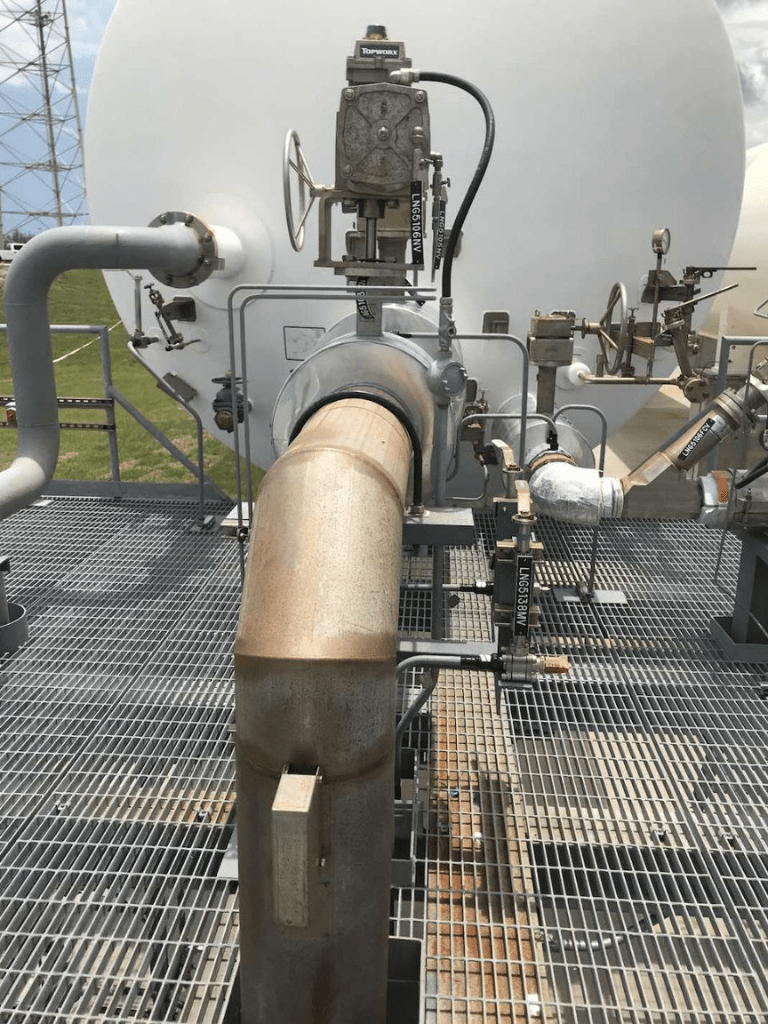

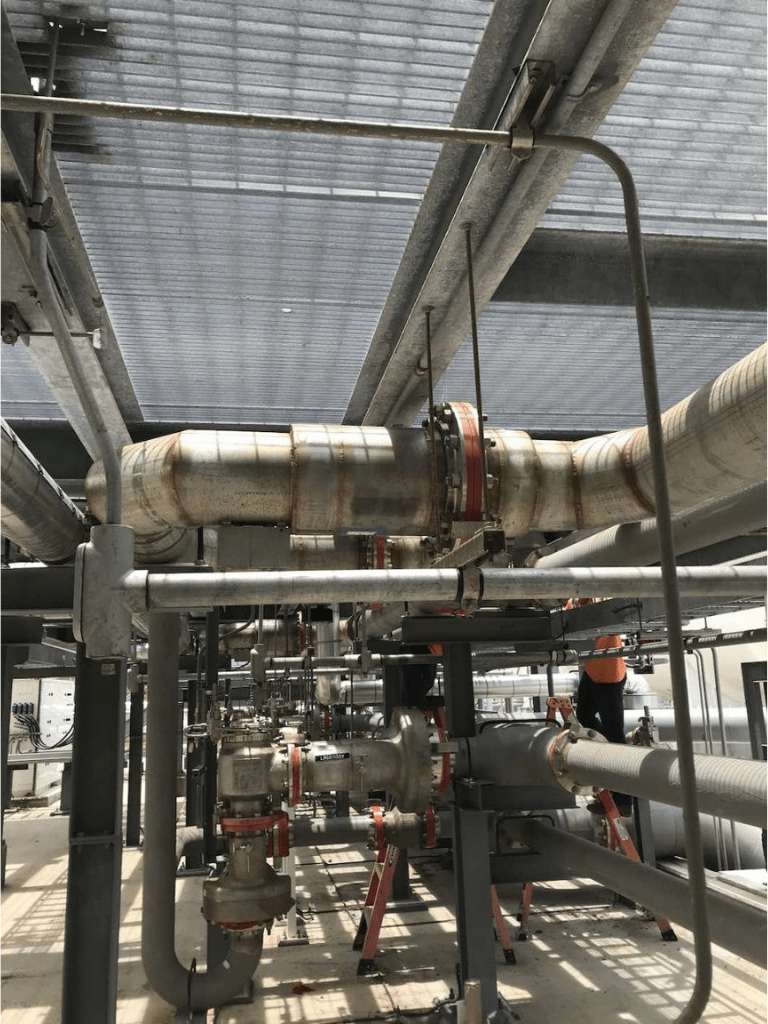

Project Name: Vulcan Launch Infrastructure Aviations

Cost: $108,600,000

Prime Contractor: Sauer Construction

Client/Owner: United Launch Alliance

Project Description: Sauer provided procurement, testing, cleaning, and installation in the VLP for ECS ductwork, control devices, vacuum jacketed and single wall cryogenic piping, in-line components, cold shock testing, functional and leak testing, insulation, autocouplers, decouplers and launch head installations, ASWS tank and system, pneumatic storage vessels and related system, World Purge system, hydraulic and cooling systems, deluge system, panel installation, and all interconnecting purge, actuation, and pneumatic pipe and tubing associated with LNG, BLO, CLO, CLH, GHE, GN2, HGDS, WP, ASWS systems.

OUR PROJECTS

Florida Theatre

Project Name: Florida Theatre

Cost: $2,286,464

Client Owner: Florida Theatre

Project Description: Sauer Mechanical is proud to participate in the historic Florida Theatre renovation. During the shut-down period we replaced the aging rooftop chillers with new Daikin air cooled chillers, as well as replacing the sixth-floor custom built air handler and outdoor air unit with all associated chilled water piping, air distribution. HVAC upgrades performed during this phase also included demolition of the boiler system no longer in use, replacing restroom exhaust fans, and upgrading the controls system

OUR PROJECTS

NASA PHSF Modifications for Psyche and Europa Clipper Missions

Cost: $1.9 million

Nominated for Distinguished Engineering Project Award by The Engineer’s Council

Project Description: Exceptional teamwork and engineering excellence by Sauer Mechanical, responsible for the replacement of ductwork and associated equipment at the Payload Hazardous Servicing Facility (PHSF), led to the successful completion of multiple phases of this critical project – safely and on-time – in support of multi-billion-dollar Interplanetary Science missions processed by the Launch Services Program at NASA Kennedy Space Center (KSC). This team operated in a unique time-constrained environment where each phase of the project was designed and constructed to fit between pre-established launch windows that could not slip even by a day.

The team’s strategic planning and persistence ensured that the replacement and modifications to multiple critical facility systems were completed within these windows and without a single construction contract extension – despite adding significant extra customer scope throughout each project’s lifecycle. The additional work that the team was able to accept and execute for the customer included multiple improvements to reduce and eliminate insect intrusion that had plagued previous processing efforts, as well as fully replace more than 150 HEPA filters, most of which were at nearly 100 feet above the ground in the cleanroom. Of significant accomplishment was the Herculean effort to safely remove and replace all these HEPA filters at extreme heights, while still operating the facility with full HVAC capacity while maintaining cleanroom particle counts

The team’s commitment to engineering excellence, teamwork, and mission success ensured the successful on-time processing of the approximately $1 billion Psyche mission (successfully launched in 2023) and enables the approximately $5 billion Europa Clipper mission processing in early 2024 (on-schedule) with their respective goals to explore the building blocks of planets and the origins of life in our Solar System.

WHAT WE OFFER

Capabilities

LET'S WORK

Contact Us

Sauer Mechanical places a strong emphasis on safety culture. We focus on exceeding the minimum guidelines set by The Occupational Safety and Health Administration (OSHA). We begin by providing our leadership with high quality safety training which flows through all employees to ensure we follow all regulatory guidelines and industry best practices.